Bearings

The roller bearing has been one of the most important machine elements for no less than two hundred years. The most important task of the roller bearing is to transmit the loads between parts of a machine moving in relation to one another, at the same time preventing them touching – in a similar way to plain bearings.

The characteristic feature of a roller bearing is that different rolling elements e.g. balls, rollers or needles, cylindrical rollers or tapered rollers are used between the inner and outer bearing race depending on the application purpose; the rolling of these elements between the races transforms undesirable slide friction into rolling friction. A distinction is made between two roller bearing variants: point-contact ball bearings and line-contact roller bearings. The friction surface of a roller bearing differs depending on the extent of the contact area.

- Line contact over larger contact areas allow greater loads to be transmitted.

- In the case of point contact with reduced surface, energy efficiency is achieved by minimising the friction surface.

Roller bearing friction is reduced even further by oil or grease lubrication. The lubricant oil in particular additionally ensures the dissipation of heat generated by bearing friction.

The geometry of a rolling element not only determines the loads to be transmitted in terms of size and direction, its contact area in conjunction with mass determines the static (load ratings) and dynamic (limit speed, friction, dynamic load rating) characteristics of the roller bearing. Depending on the bearing load and the respective rigidity, the rolling element may be compressed in the respective raceway.

Thanks to international standardisation, roller bearings can now be exchanged all over the world. The modern design using high-purity steel guarantees extremely high precision with minimum tolerances. In addition, further performance ranges and applications can be achieved thanks to an optimised design with contemporary production accuracy thanks to intelligent software and modern materials such as vacuum-degassed roller bearing steels, low-corrosion stainless steels, ceramics or innovative polymers.

For more than 20 years, NBR has been supplying an optimum selection of bearings suitable for specific applications in terms of price, performance and availability.

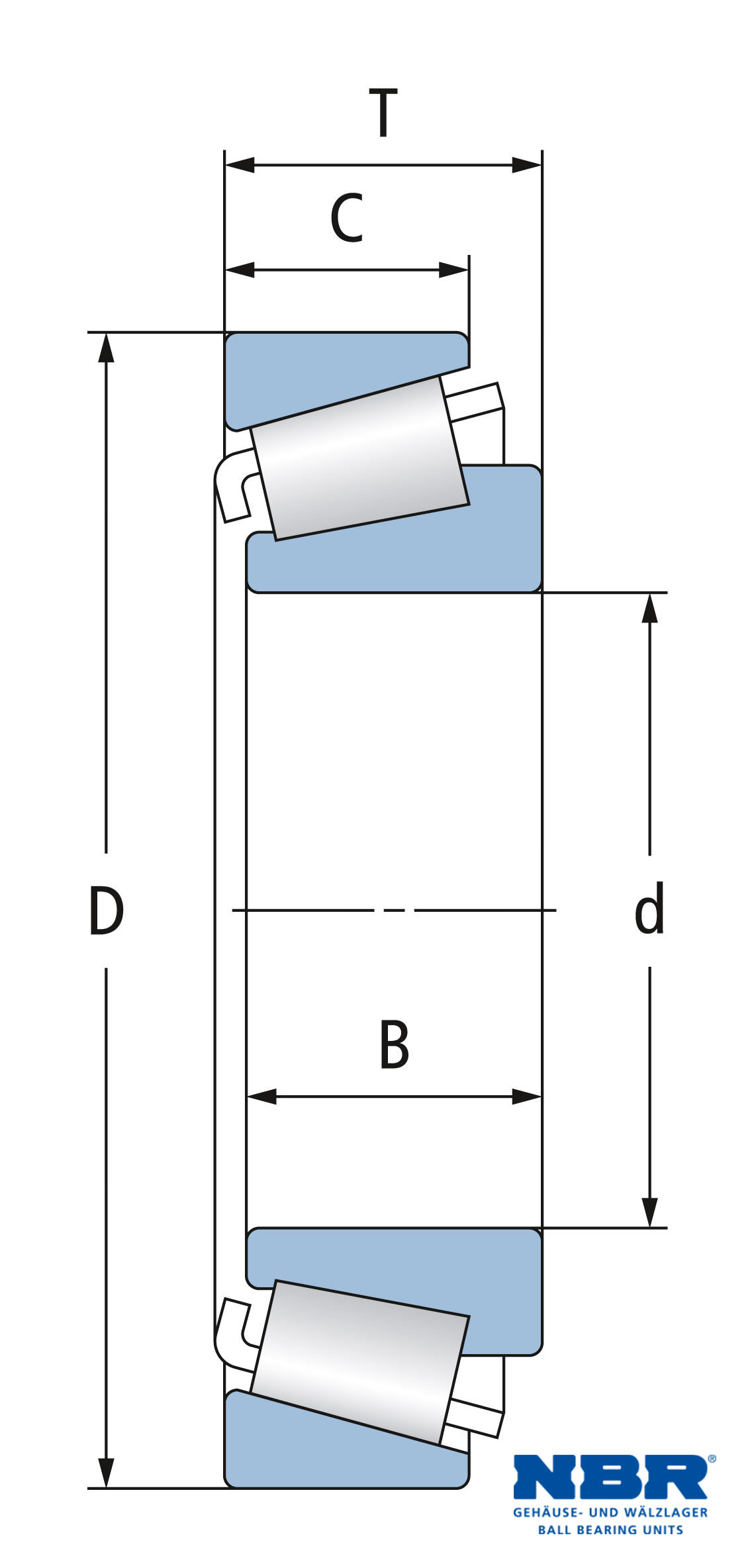

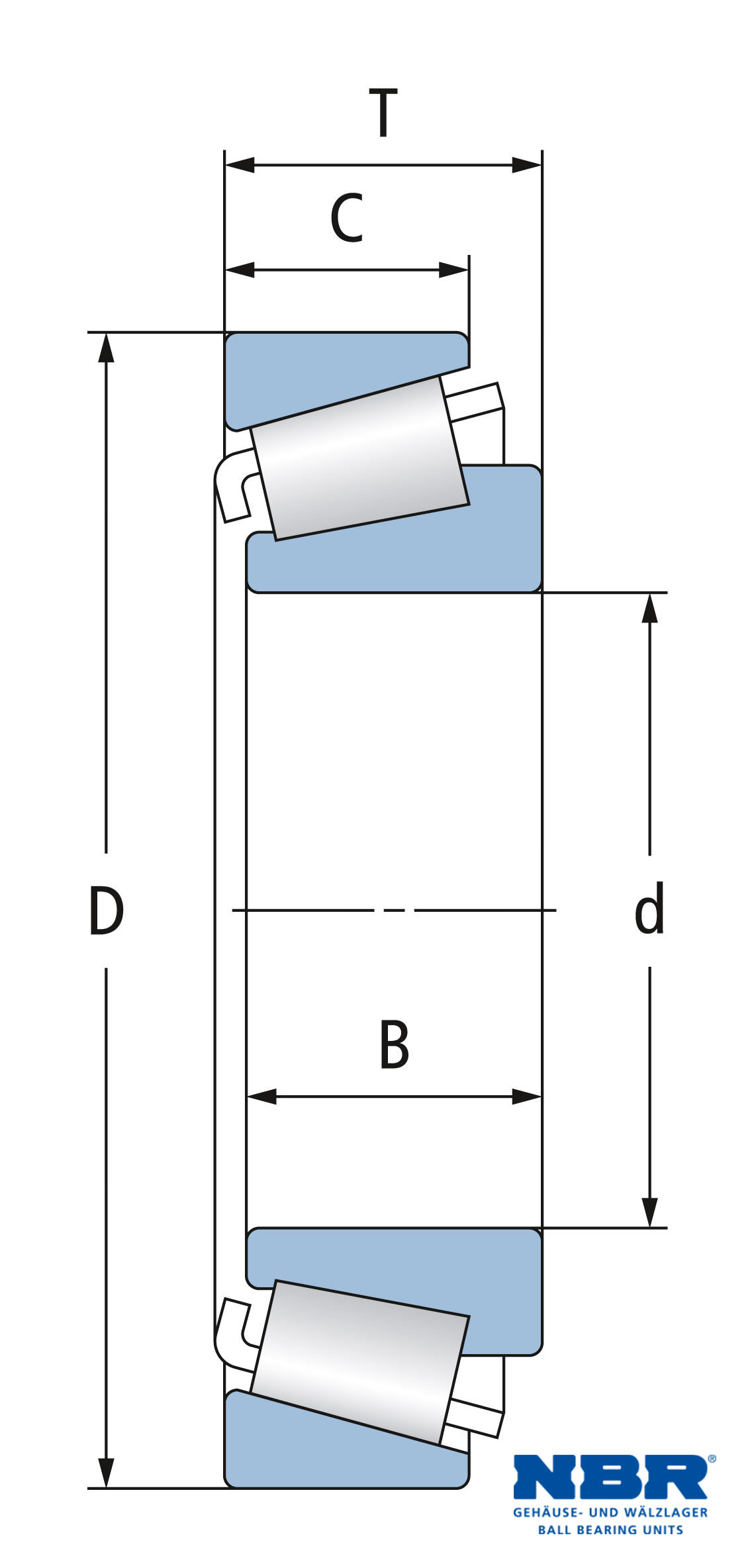

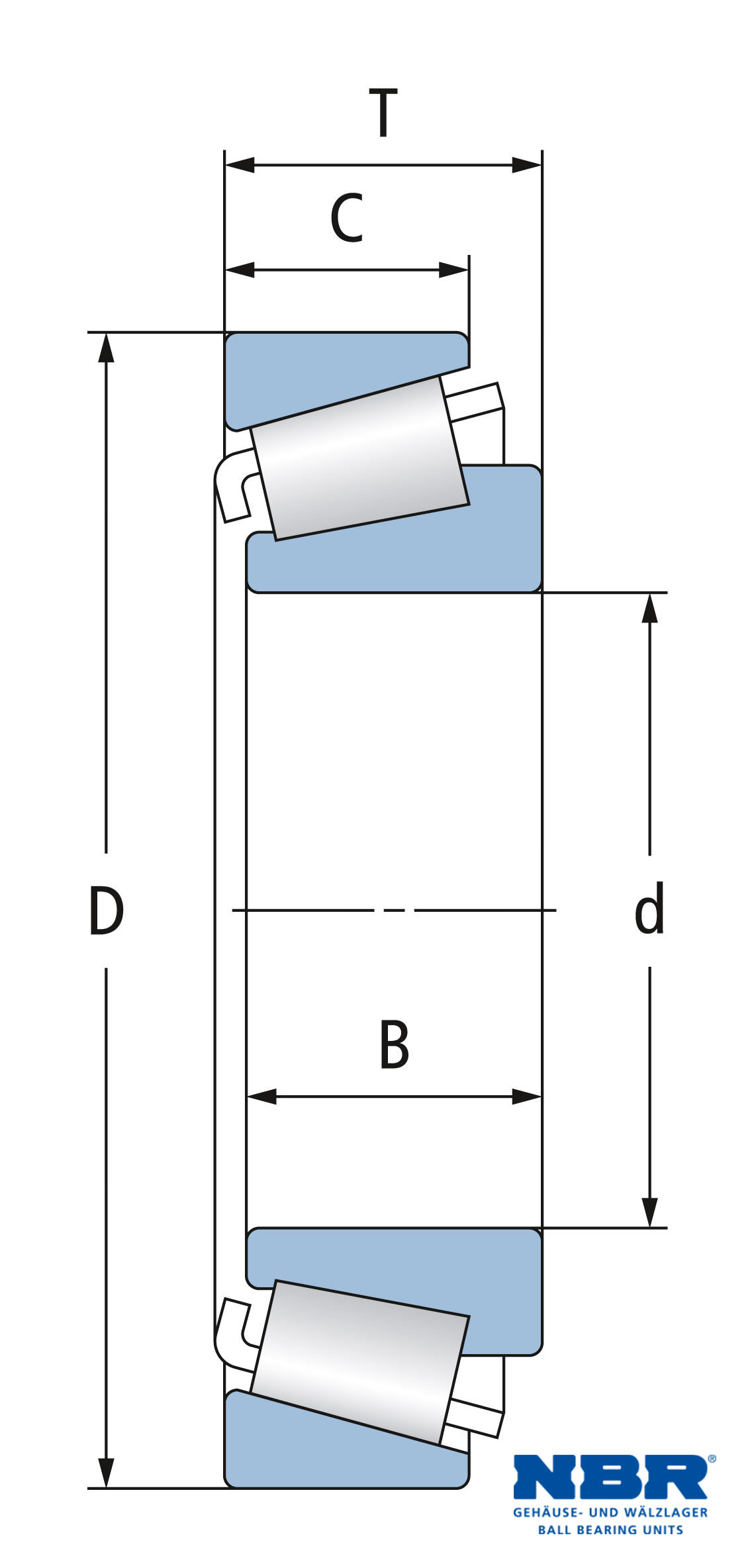

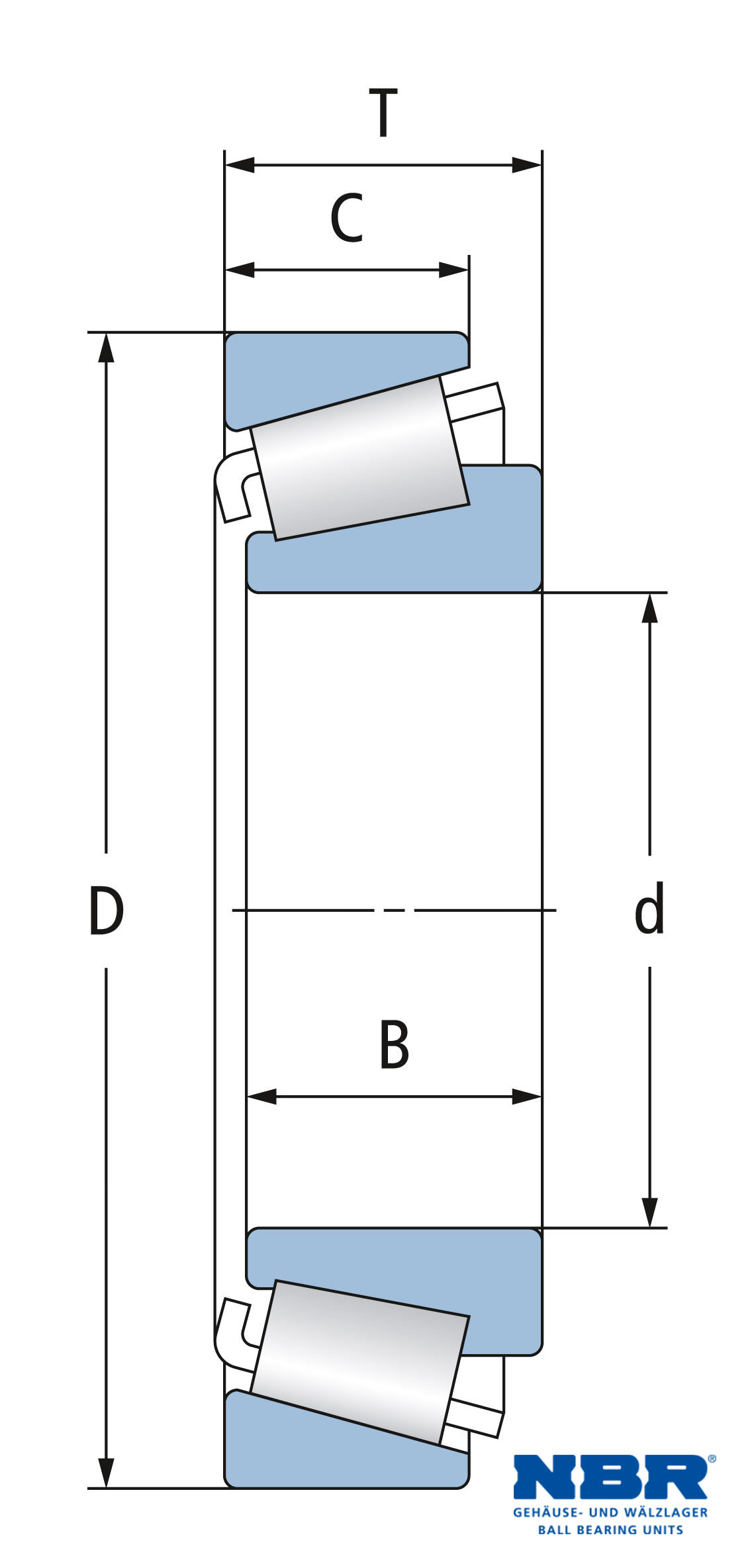

- d (mm)22

- D (mm)50

- B (mm)14

- C (mm)12

- T (mm)15,25

- Gewicht in kg0,144

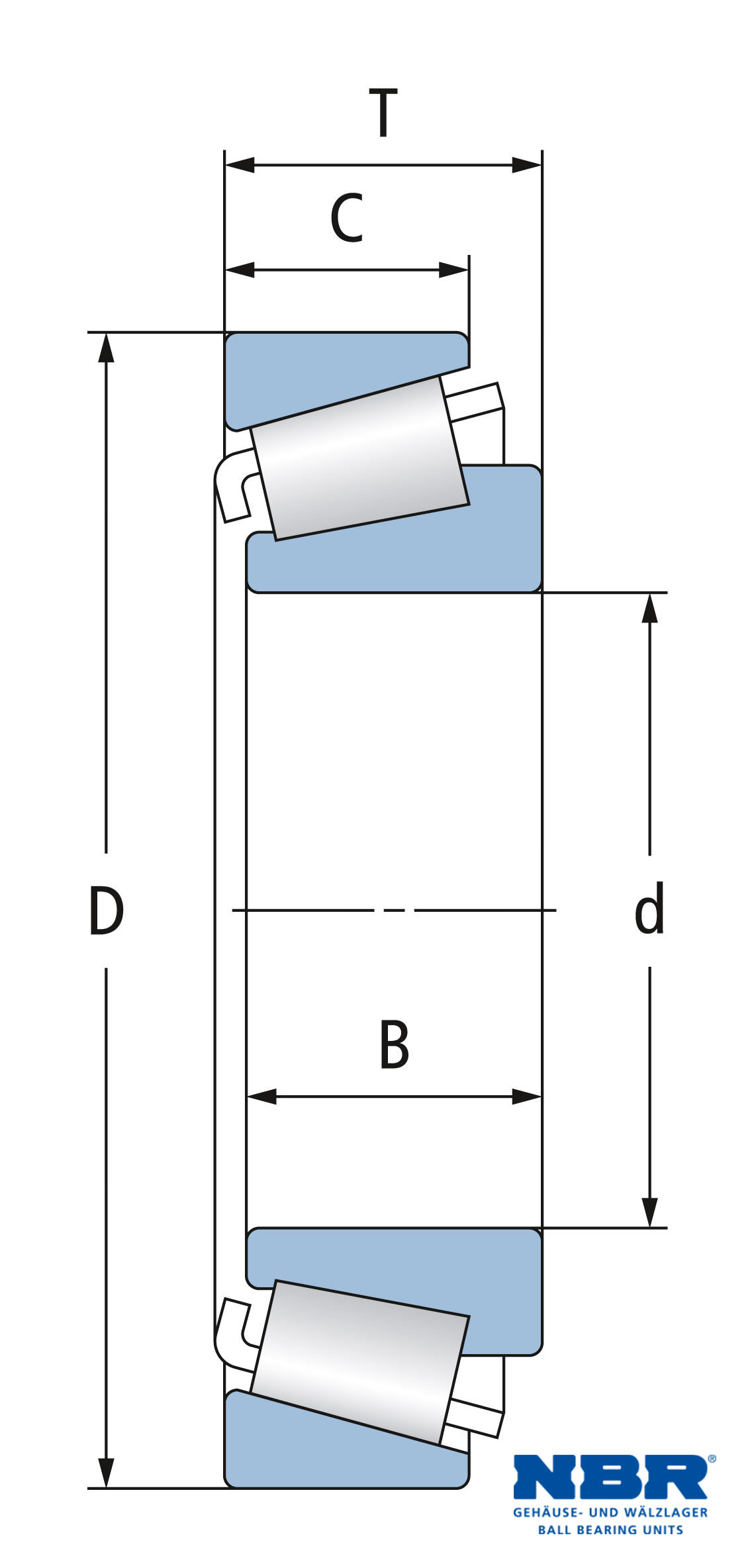

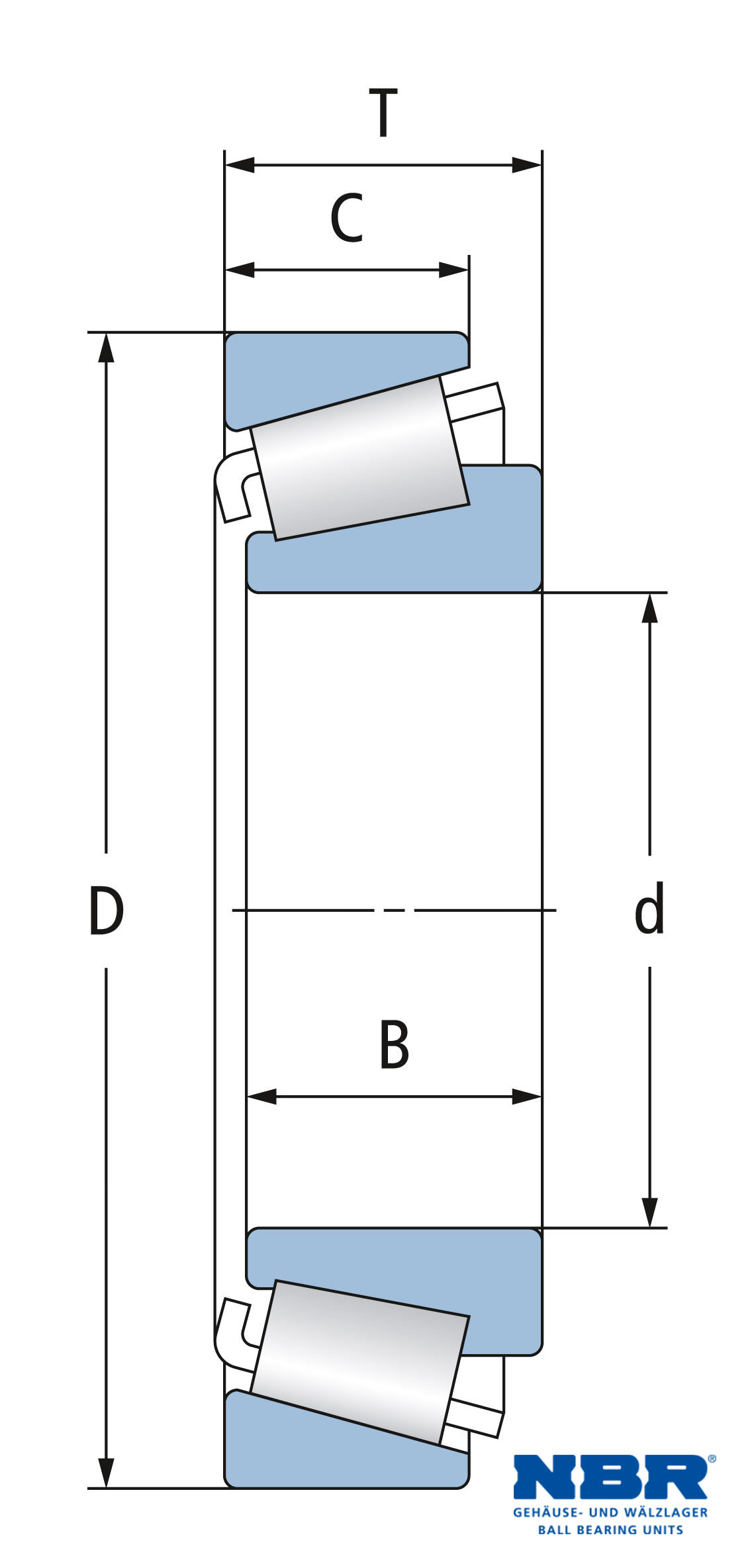

- d (mm)28

- D (mm)58

- B (mm)16

- C (mm)14

- T (mm)17,25

- Gewicht in kg0,209

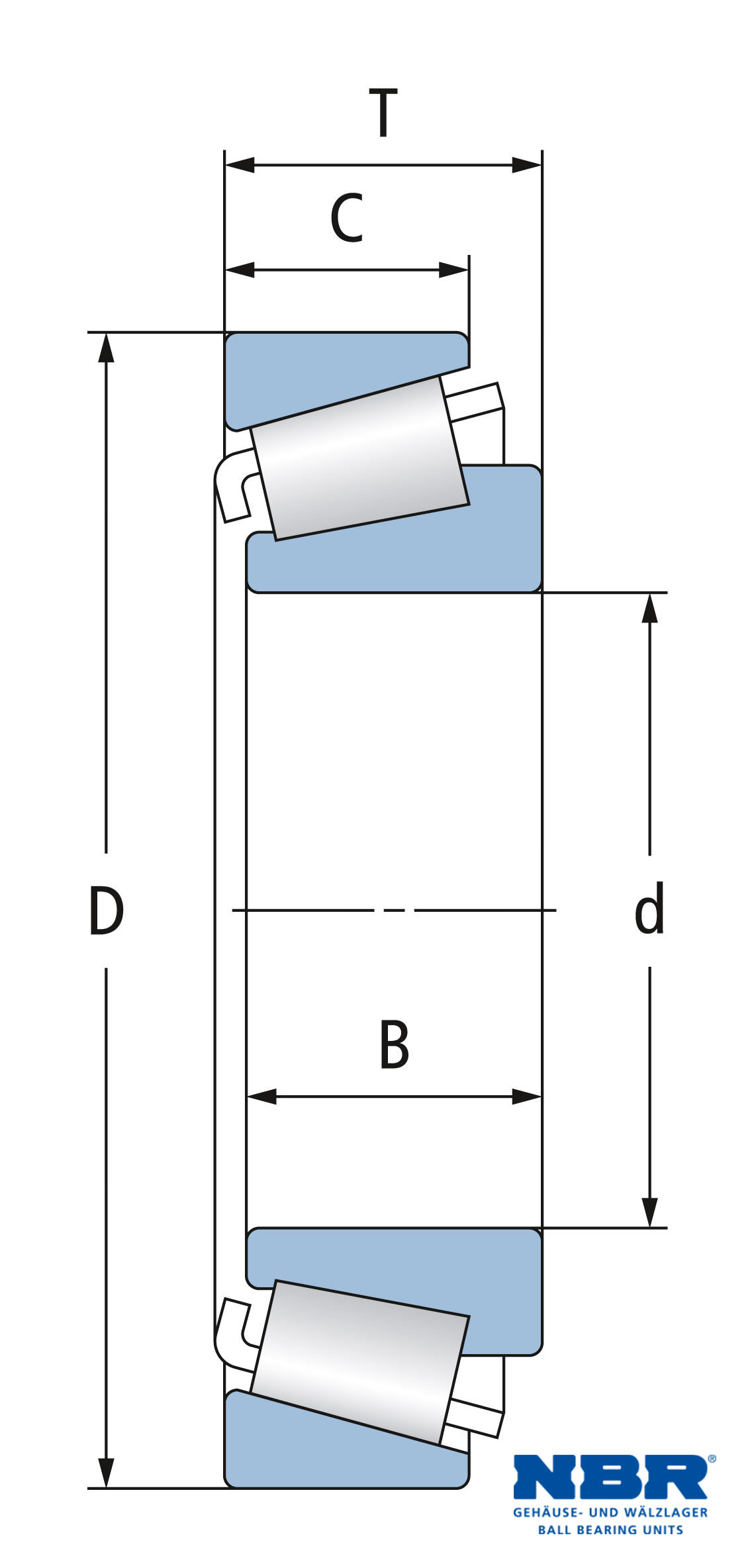

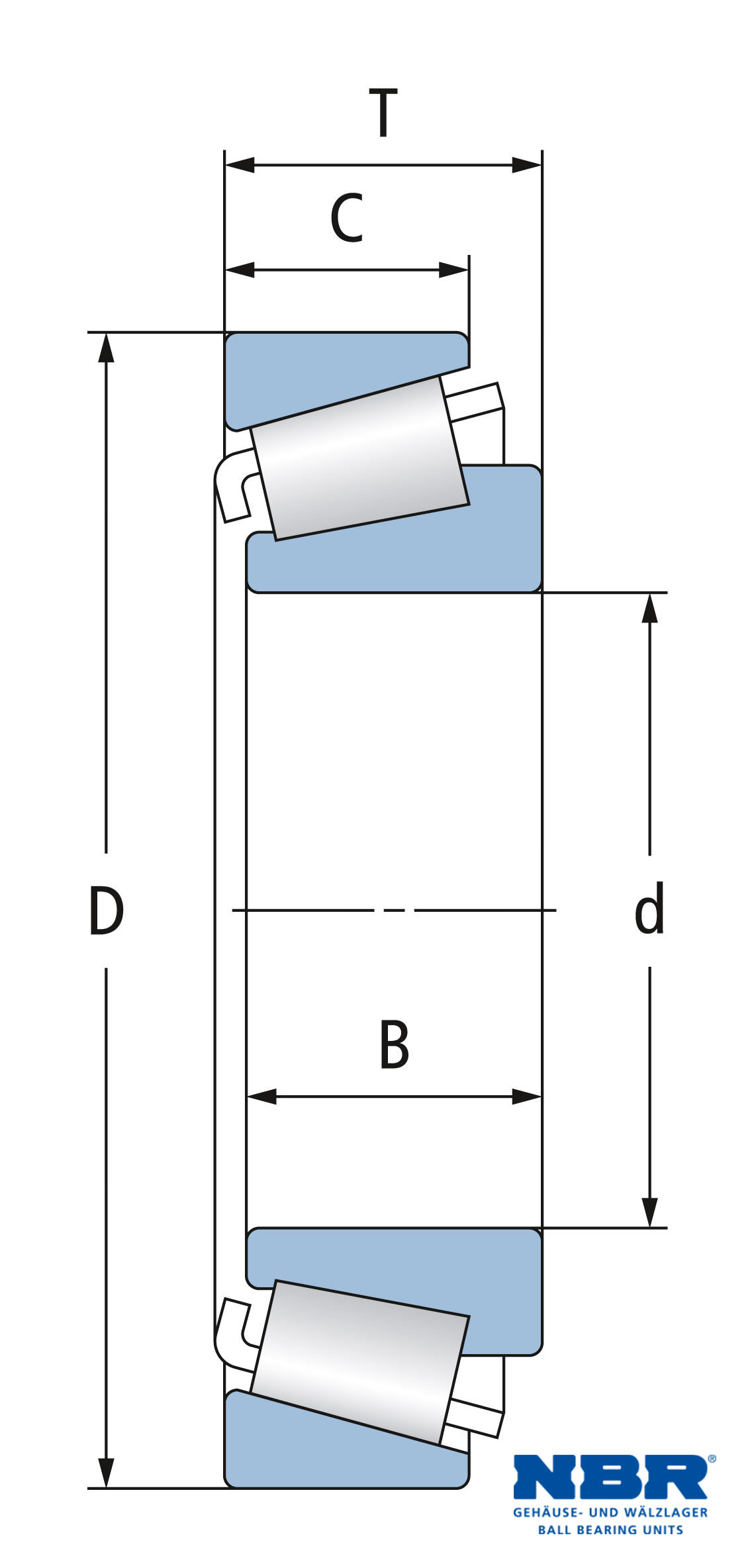

- d (mm)15

- D (mm)35

- B (mm)11

- C (mm)10

- T (mm)11,75

- Gewicht in kg0,054

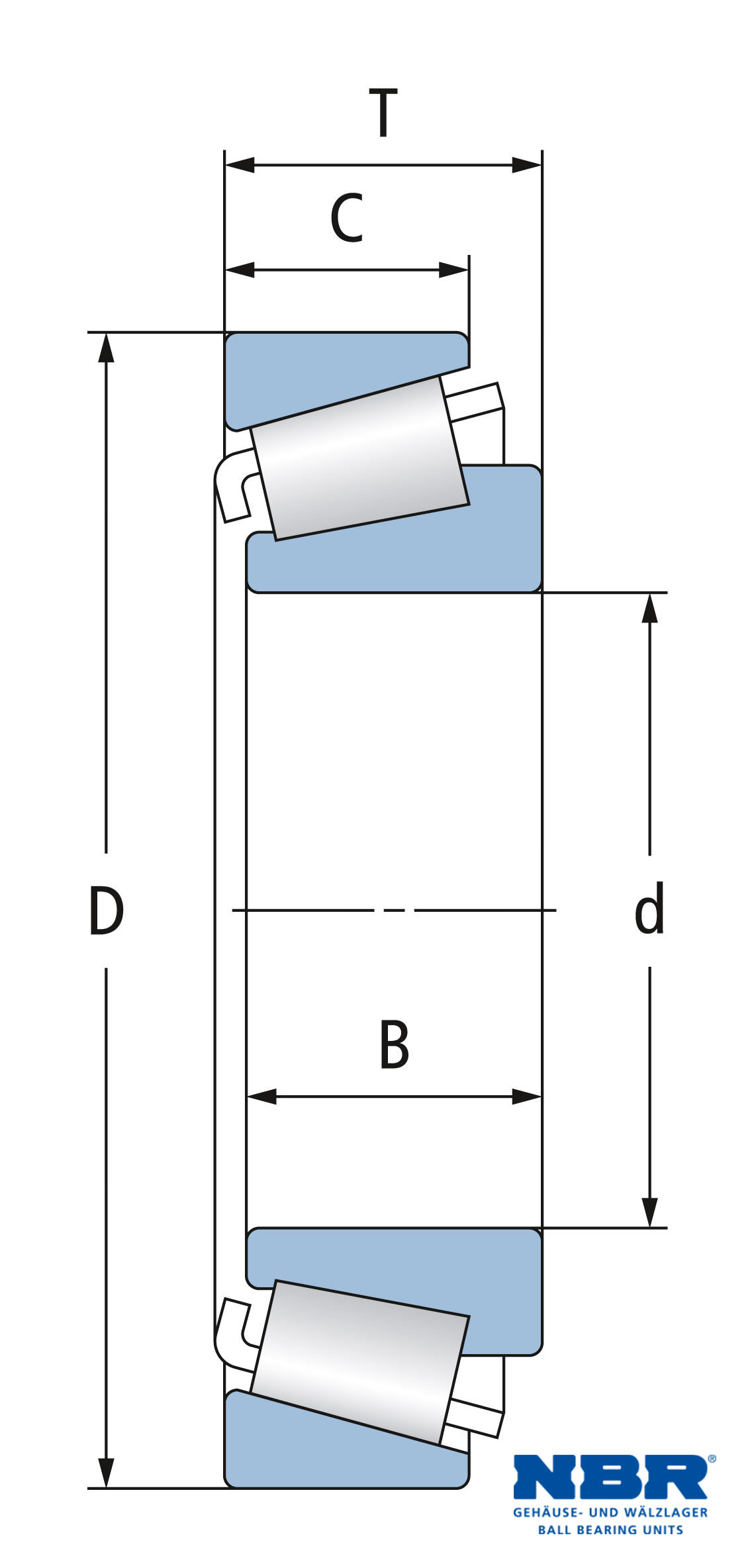

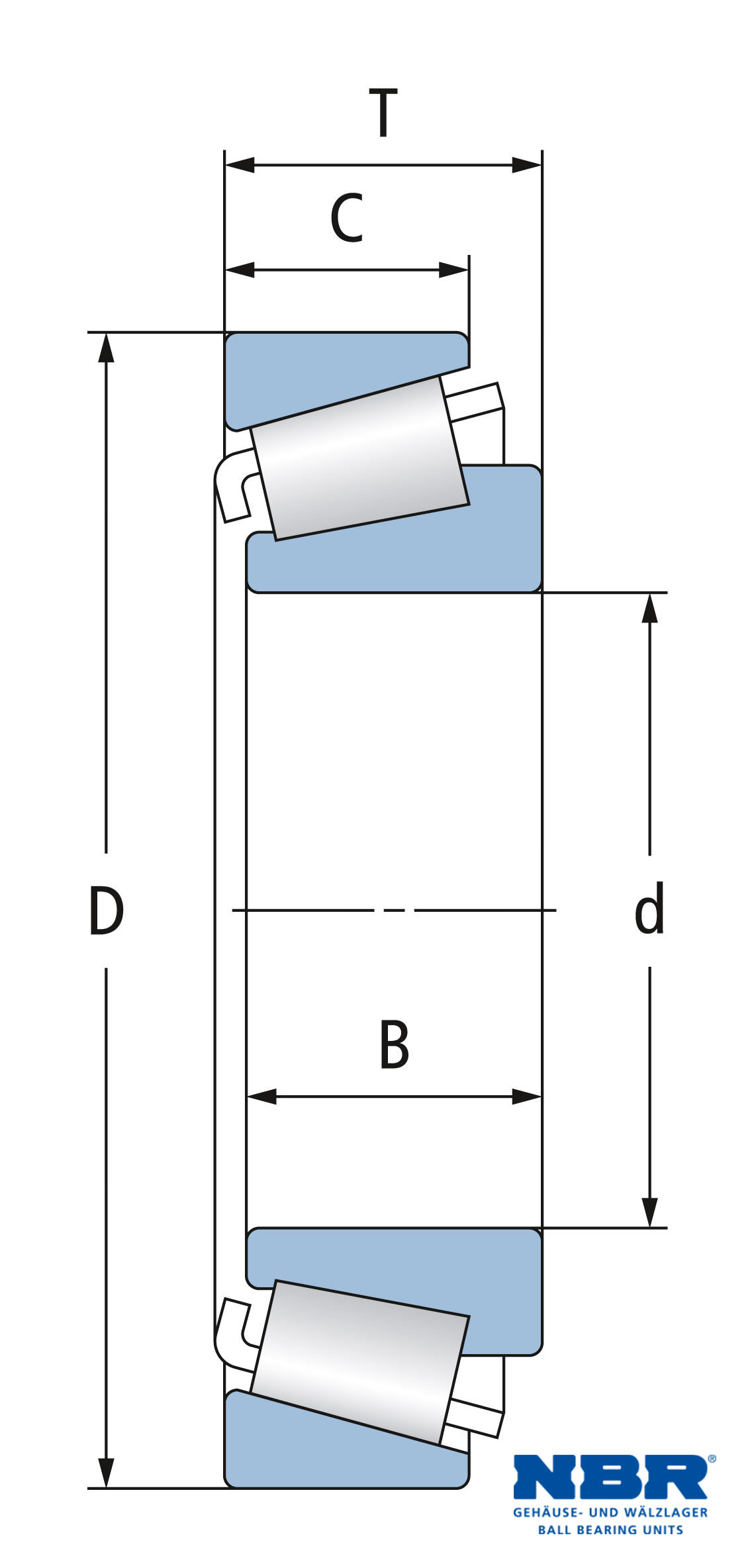

- d (mm)17

- D (mm)40

- B (mm)12

- C (mm)11

- T (mm)13,25

- Gewicht in kg0,081

- d (mm)20

- D (mm)47

- B (mm)14

- C (mm)12

- T (mm)15,25

- Gewicht in kg0,127

- d (mm)25

- D (mm)52

- B (mm)15

- C (mm)13

- T (mm)16,25

- Gewicht in kg0,156

- d (mm)30

- D (mm)62

- B (mm)16

- C (mm)14

- T (mm)17,25

- Gewicht in kg0,236

- d (mm)35

- D (mm)72

- B (mm)17

- C (mm)15

- T (mm)18,25

- Gewicht in kg0,344

- d (mm)40

- D (mm)80

- B (mm)18

- C (mm)16

- T (mm)19,75

- Gewicht in kg0,434

- d (mm)45

- D (mm)85

- B (mm)19

- C (mm)16

- T (mm)20,75

- Gewicht in kg0,502